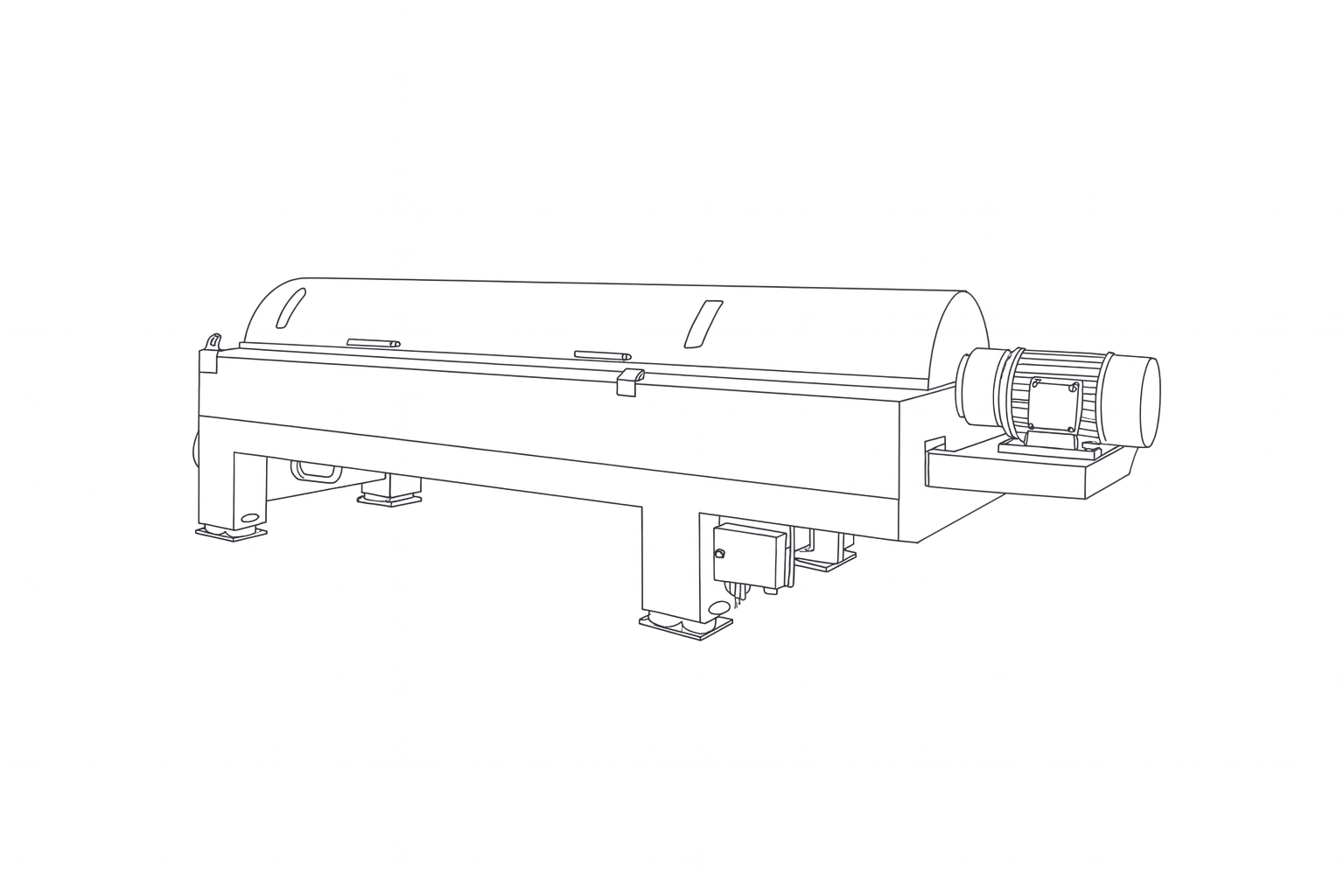

Alfa Laval Centrifuges

Alfa Laval’s LYNX 430 centrifuges deliver high-performance solid-liquid separation for demanding industrial applications. Engineered for continuous operation, these decanter centrifuges efficiently remove fine solids from process streams while handling high throughputs with low maintenance requirements.

The robust design, energy-efficient drive system, and precise control features make the LYNX 430 ideal for industries where uptime and separation quality are critical.

Key Usage Cases

Sludge dewatering in municipal and industrial wastewater treatment

Solids removal in oil & gas drilling mud and produced water

Clarification of process liquids in food and beverage production

Mining and mineral processing slurry separation

Pulp and paper mill wastewater treatment

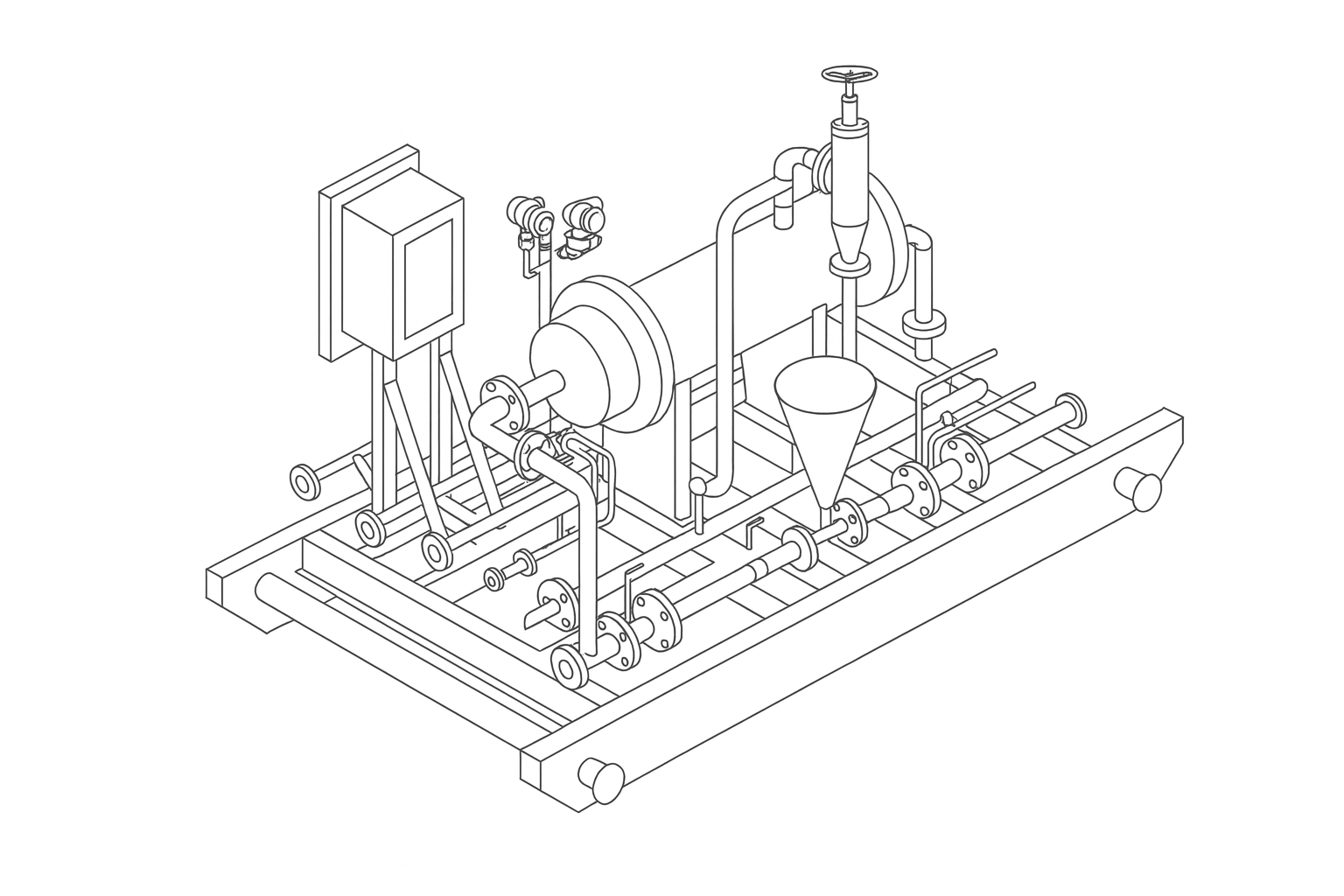

Veolia Cyclonics

Veolia’s cyclonic separation systems deliver efficient removal of solids and liquids from process streams using high-speed centrifugal forces.

Designed for durability and minimal maintenance, these hydrocyclones and wellhead separators operate without moving parts, making them ideal for demanding oil & gas, mining, and industrial water treatment applications. Their compact footprint and high separation efficiency reduce downstream filtration loads and extend equipment life.

Key Usage Cases

Solids removal in produced water treatment

Sand and silt separation in oil & gas production

Protection of downstream pumps and membranes

Bulk separation before fine filtration

Removal of heavy solids in mining and mineral processing

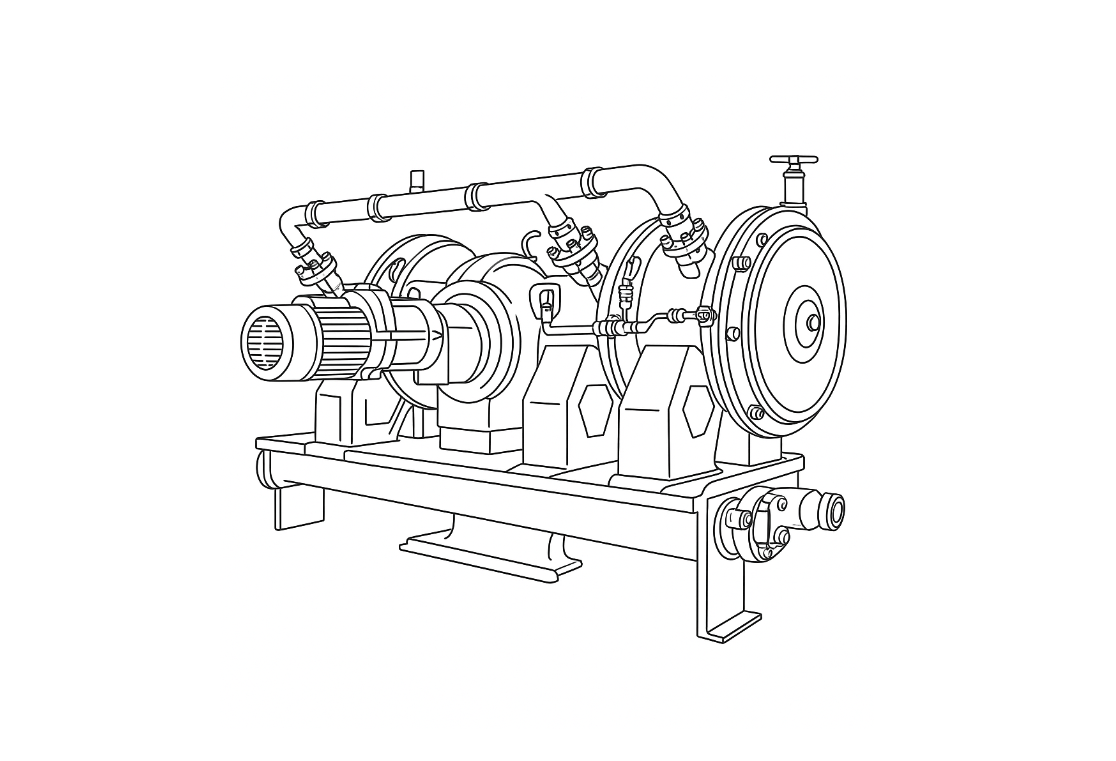

Fournier Presses

Fournier Rotary Presses provide high-performance, continuous sludge dewatering for municipal and industrial applications. The unique slow-rotation design gently compresses sludge between rotating screens, producing a high-solids cake while maintaining exceptional capture rates.

Fully enclosed operation eliminates odor, aerosol, and spillage concerns, making the presses suitable for installations in sensitive environments. The compact footprint, low energy requirements, and automated controls allow for simple integration into both new builds and retrofit projects, reducing operational costs and improving dewatering reliability.

Key Usage Cases

Sludge dewatering in municipal wastewater plants

Industrial sludge treatment in food processing, pulp & paper, and mining

Low-maintenance dewatering for remote or unmanned facilities

Odor-controlled sludge handling in urban or enclosed sites

Replacement for high-speed centrifuges or belt presses to reduce OPEX