Triton Dissolved Air Flotation

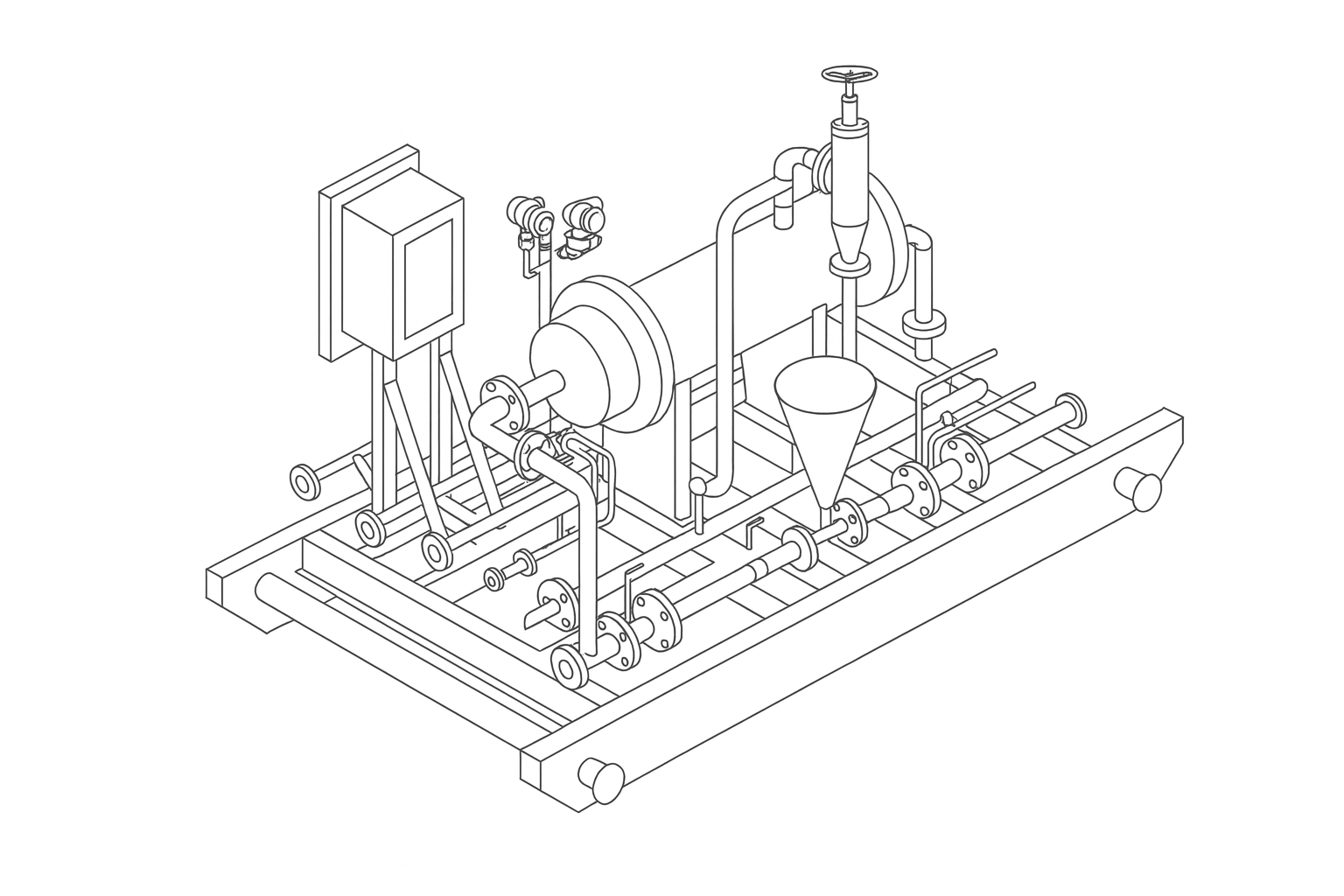

DAF4™ Zero Emissions DAF: Compact, trailer or skid-mounted unit with a sealed top to eliminate emissions. Features a settling solids hopper system, integrated controls, and rapid deployment for mobile wastewater treatment in industrial and oil & gas applications.

High-Capacity DAF: Large-scale system handling up to 100,000 bwpd (2,917 USGPM) with turnkey setup for fast startups. Includes direct drive mechanical skimmer, integrated controls and piping, and a solids hopper for efficient, high-volume wastewater clarification.

Key Usage Cases

Industrial wastewater clarification

Pretreatment for membrane filtration or biological systems

Oil and grease removal in food processing

Produced water treatment in oil & gas

Triton Sour Water Oxidation

Triton’s Sour Water Oxidation systems are engineered for the treatment of hydrogen sulfide (H₂S) and ammonia-laden wastewater streams generated in refining, petrochemical, and industrial processes. Using advanced oxidation technology, these systems convert harmful sulfides and ammonia into environmentally safe compounds, ensuring compliance with stringent discharge standards.

Designed for reliability, low chemical consumption, and minimal operator intervention, Triton units are available in skid-mounted or containerized configurations for seamless integration into existing operations.

Key Usage Cases

Treatment of sour water from oil refineries and petrochemical plants

H₂S and ammonia removal from industrial wastewater

Compliance with environmental discharge regulations

Pretreatment for biological or membrane-based polishing systems

Integration into zero-liquid-discharge treatment schemes

Veolia Dissolved Air Flotation

Veolia’s Dissolved Air Flotation (DAF) systems provide high-efficiency separation of suspended solids, oils, and greases from wastewater. By dissolving air into water under pressure and then releasing it, microscopic air bubbles attach to contaminants, causing them to float to the surface for easy removal.

Designed for industrial and municipal applications, Veolia DAF units deliver reliable performance, low operating costs, and compliance with stringent discharge standards.

Key Usage Cases

Industrial wastewater clarification

Pretreatment for membrane filtration or biological systems

Oil and grease removal in food processing

Produced water treatment in oil & gas

Veolia Cyclonics

Veolia’s cyclonic separation systems deliver efficient removal of solids and liquids from process streams using high-speed centrifugal forces.

Designed for durability and minimal maintenance, these hydrocyclones and wellhead separators operate without moving parts, making them ideal for demanding oil & gas, mining, and industrial water treatment applications. Their compact footprint and high separation efficiency reduce downstream filtration loads and extend equipment life.

Key Usage Cases

Solids removal in produced water treatment

Sand and silt separation in oil & gas production

Protection of downstream pumps and membranes

Bulk separation before fine filtration

Removal of heavy solids in mining and mineral processing

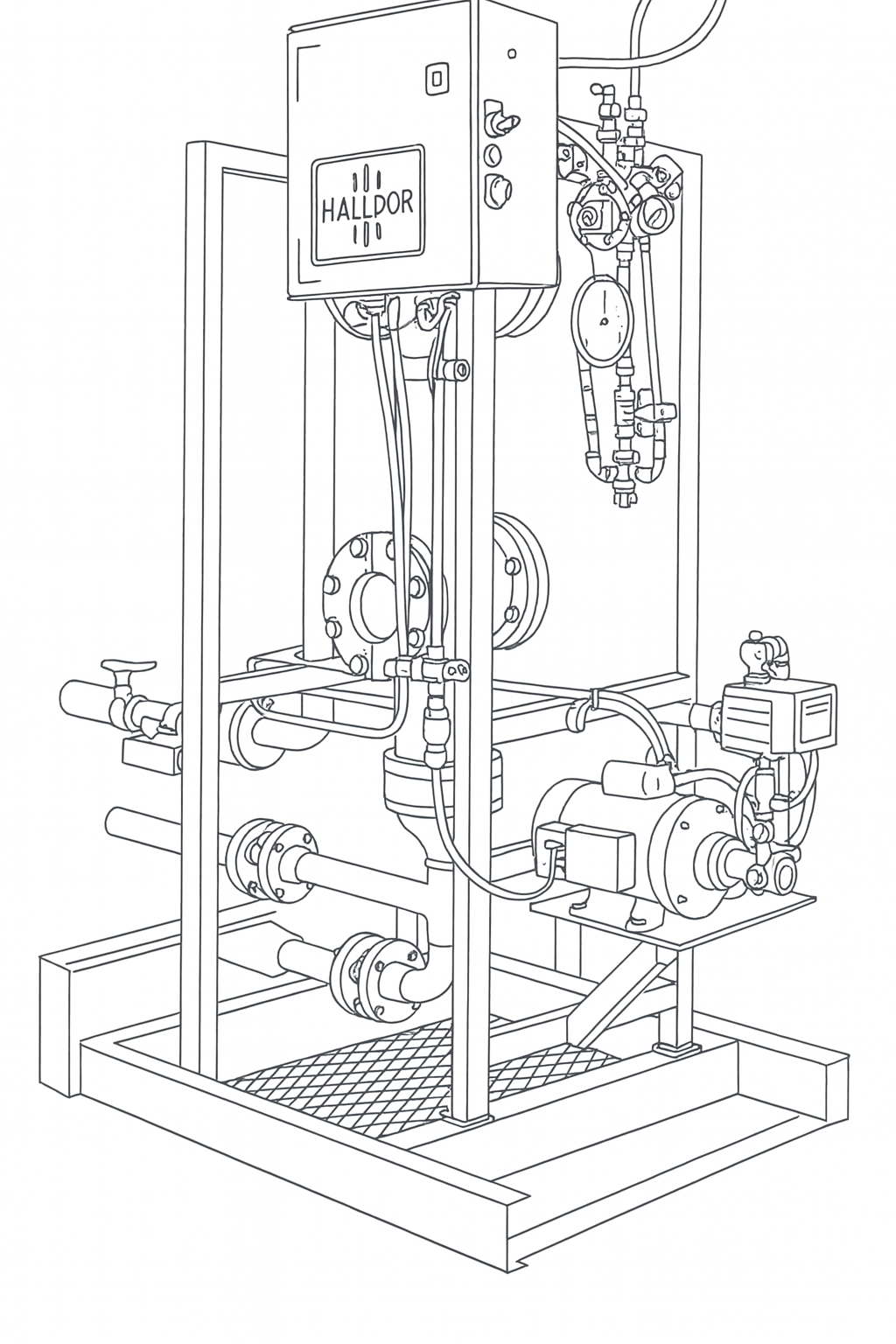

Halldor Filters

Halldor Filters are engineered for high-solids applications that challenge traditional self-cleaning filtration systems. Unlike conventional designs, GeyserPURGE™ technology concentrates solids before purging, reducing purge frequency, minimizing water loss, and significantly lowering waste volumes.

GeyserPURGE™ series offers scalable solutions from compact single-unit systems to advanced dual-stage and high-capacity purge models. This self-cleaning capability ensures continuous operation, reduced maintenance downtime, and dependable filtration performance in demanding environments.

Key Usage Cases

Continuous filtration in high-solids process streams

Applications requiring minimal water loss during purging

Industrial wastewater and process water treatment

Pretreatment to protect downstream filtration or membrane systems

Operations in remote or unmanned facilities

Pivotal Fluid Solutions Cyclonics

The STIXX enhanced gravity separation platform is engineered for high efficiency separation of solids and residual oil from produced water. STIXX delivers excellent performance without the need for chemicals in most cases. This cleaner produced water reduces load on downstream equipment and downstream chemical usage (ex. reduced HP injection and DAF loading).

Designed in 10,000 bpd internal modules allow sizing from 10,000 bpd to 100,000 bpd in a single shipping container including the pumps. This allows the system to grow and shrink as operating conditions change without altering the layout or tie-ins.

Key Usage Cases

Solids removal in produced water treatment

Sand and silt separation in oil & gas production

Protection of downstream pumps and membranes

Bulk separation before fine filtration

Removal of heavy solids in mining and mineral processing

Enerflex Gas Flotation

Enerflex gas flotation systems are designed for high-efficiency removal of oil, grease, and suspended solids from produced water using induced gas flotation technology.

Built for durability, these systems feature a compact design, corrosion-resistant construction, and easy maintenance access. Available in multiple configurations, including horizontal and vertical designs, Enerflex units are optimized for reliable operation, compliance with strict discharge regulations, and integration into both new builds and retrofit projects.

Key Usage Cases

Produced water treatment in oil & gas operations

Offshore platform water discharge compliance

Oil and grease removal in industrial wastewater

Pretreatment before membrane or filtration systems

High-efficiency separation for retrofit and new-build projects

MyCelX Filtration

MyCelX media filtration systems are engineered for high-efficiency removal of oil, hydrocarbons, PFAS, and other persistent contaminants from water. Using proprietary MyCelX media, these systems chemically bond with target pollutants, ensuring permanent removal without secondary waste streams.

Compact and modular, they are designed for quick deployment, easy change-outs, and consistent performance in challenging industrial and environmental applications.

Key Usage Cases

Removal of oil and hydrocarbons from produced water

PFAS elimination in industrial and municipal treatment

Pretreatment for RO, UF, or other polishing systems

Stormwater and runoff treatment at industrial sites

Emergency spill response and remediation projects

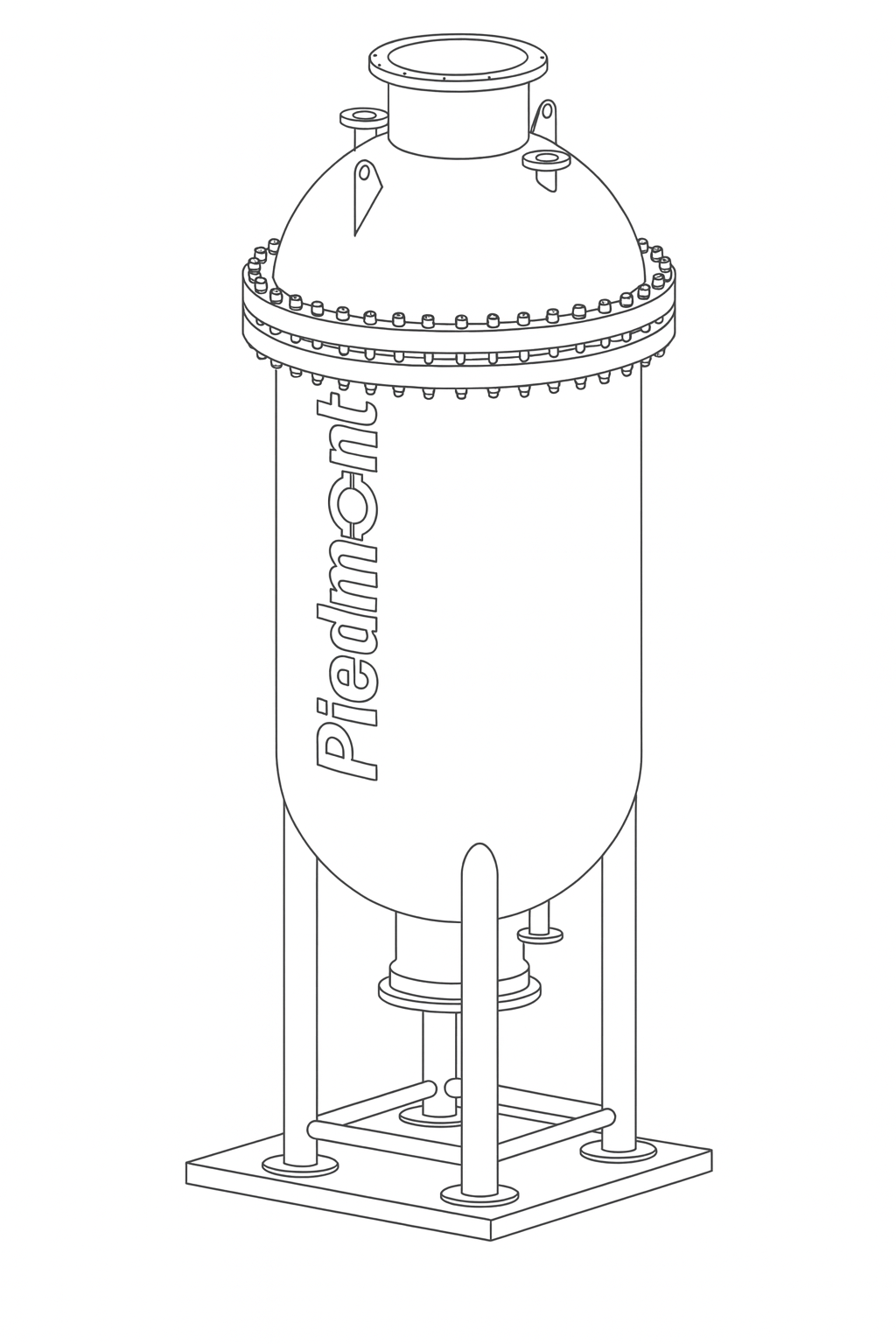

Piedmont Filtration

Piedmont cartridge and bag filtration systems provide reliable, high-capacity removal of suspended solids and fine particulates from water and process streams. Built with corrosion-resistant housings and precision-engineered filter elements, these systems are designed for long service life, easy maintenance, and flexible configuration.

Ideal for industrial, municipal, and commercial applications, Piedmont filters deliver consistent water quality while protecting downstream equipment and processes.

Key Usage Cases

Pretreatment for RO, UF, or other membrane systems

Removal of suspended solids in industrial process water

Protection of pumps, heat exchangers, and sensitive equipment

Filtration in food & beverage and pharmaceutical production

Municipal and commercial water treatment polishing